Devil's Playground Granite Glaze Tests Round 3: Pictures and Notes

In my last post, I explained the basis for this third round of glaze tests with my granite collected at Devil’s Playground. I wanted to see what various different fluxes would do to it at cone 10.

In addition to the flux tests, I also did a follow-up test with some basalt I collected, and a second test of some yellow glazes I was aiming at. Because this blog post is likely to be rather long, I will do another one dealing with the yellow glaze research. Generally speaking, this is the flux addition round of tests.

If you have any questions about any of this research, please don’t hesitate to email me. I’d love to chat!

In each of the groupings here, I have displayed the cone 10 gas reduction tiles on the top row, then the oxidation ones below them and finally the soda ones. The reduction tests have a little r in the bottom right corner of them (written in sharpie), the oxidation ones have a dot and the soda ones are marked by the flashing on the clay (n sharpie required).

I analyse these results based on my own predilections and goals, but I am sure there are folks out there who might like some of the tests that I dismiss. I also can see coming back to these tests in the future and picking out some, (that I am currently dismissing) for further testing.

In this post, I will go through each set of tests and lay out the results. Each test was fired in three atmospheres: gas oxidation, gas reduction and gas soda, all to cone 10. Click on any of the images to enlarge them and flick through the pictures in each gallery.

Okay, first up I have my second attempt with a basalt addition to the granite. This basalt came from just outside Craters of the Moon park. The results from round 2 were not great: I got a lot of dull khaki colors, but I hoped that by adding extra flux to my granite and redoing the test, I would get more promising results. So I used a mix of 80% granite with 20% lime.

Definitely some promising results from this basalt addition test. I plan to try and make this a base for a tenmoku recipe. I think I favored DP776 in gas reduction. It had 20% basalt to 80% DP mix (80:20 DP:Lime) plus 4% iron oxide. The iron brought a richness without having to use a higher % of basalt. Basalt is quite tough to grind and I do not have an unlimited supply of it, so 20% is more convenient than 40%! Trying to be as practical as possible here. I definitely will follow up on this test and try to jazz it up with some other additions, too. I think it would respond well to iron decoration.

Next up, I have the wollastonite test (yes I spelt it wrong on the paper here; something about wollastonite makes me want to think of it as woolly)…

The wollastonite test represented a big win in these experiments. Wollastonite brings both silica and calcium to the table: its chemical formula is: CaSiO3. This mix made from brighter and bluer glazes than the lime (which we will see below). Out of all the fluxes, wollastonite was the cleanest and brightest. My flux of choice with this granite!

Next up we have the lime set…

I have often used lime as a flux in the past. It supplies calcium, which is a strong flux. In general, it tends to make the glaze greener and also fairly quickly sends it matte. DP673 has a satin texture (at 30% lime) but above that we are in matte territory. The tests were remarkably stable, only threatening to drip in soda.

Next up we have spodumene (LiAl(SiO3)2) which provides lithium as a flux.

On the whole, I did not love any of the spodumene tests. They moved towards shino-like surfaces but none were that special.

Moving on to the grolleg additions. Grolleg is not a flux, although it does contain some flux. It is a blended clay from England that looks good in soda; nice flashing. I have made several successful porcelain bodies using 50% grolleg and various slips, too. In this test, I was hoping to find an attractive slip for soda firing with it. I doubted whether I would get anything interesting in gas reduction or oxidation without soda.

DP 705-13 were fairly drab but when I added 20% lime to them, the results were much nicer. I did not arrive at a tasty soda slip but I did get some intriguing results. DP714-8 were nice blue celadons. It shows how important the flux in the glaze is for color response! With clay, too, I am sure.

Moving on to adding borax to the granite…

The borax did some really interesting things. Especially when I added 4% iron to the mix. In chatting to John Neely about these tests, he said boron (which borax is made up of) melts early on, so it creates some phase separation in the glaze. There were some oily surfaces which I quite liked, and I see a lot of potential here for further experimentation. Seems like as little as 10% makes things more interesting.

Next up: soda ash…

This was an interesting set of results. I got a fair bit of bubbling in oxidation (due mostly to a fast firing I think)… this happened to some of the sets of tests but not others. Anyway it was particularly potent with the soda ash tests. The tests that I found most promising were DP 747-52 in soda. They came out kind of splotchy, almost like ink in water. Quite an interesting effect. It makes me want to try adding soda ash to some other glaze formulations to see what happens.

Now the minspar (a soda feldspar) addition…

These results were similar to the spodumene tests. None too exciting. In soda they tended towards grey/brown and not very nice browns with extra iron added in.

Now the custer feldspar (a potash feldspar) addition…

These results were very similar to the minspar addition and spodumene too. Nothing to write home about!

Next up is strontium carbonate (SrCO3)…

In reduction I got some pretty nice color out of the strontium carbonate addition. It was similar to the wollastonite, which I was wowed by, except a little darker. Started to get drippy with 45-50% added. DP 899-900 were nice.

Next up we have zinc oxide…

There were some pretty exciting results from this set. In reduction, that is. The action was all in reduction. Without iron added I got some interesting kind of goldish tones on mostly cream DP921-3. But when I added the 4% iron things got wild. All the way from 5% zinc oxide up to 50%, there were interesting flecks and colors happening. I will be experimenting more with this!

Next up is petalite (another lithium bearing material)…

The results here were very similar to spodumene, similar to minspar and custer feldspar as well. Nothing that interesting really.

Next up we have magnesium carbonate…

I was not expecting these results. Heavy crawling effects! I did not know when I ran the test that magnesium carbonate is often used to make glazes that crawl in a big way. This is not what I am going for right now, but could be interesting on a sculpture or something like that. One interesting thing to note is the difference between the oxidation and reduction firing.

You can see this in the tile DP 943 above. The reduction firing cycle is much longer than the oxidation cycle… this lead to a difference in the crawling effect. In the oxidation tile, it is more pronounced: the glaze cooled before it had a chance to melt over and heal. This healing started to happen on the reduction tile. We also see more of the crawling effect in the set without iron. The extra flux of the iron caused more melting in the glaze and less crawling.

Okay! Last one! End on a bang! Here we have the lithium carbonate addition…

I made full sets of these lithium carbonate tests but most of them physically broke. The glazes aggressively did not fit. Steer clear of lithium carbonate! John Neely told me that lithium carbonate has a very low thermal expansion; negative thermal expansion, even. So it just will not fit a normal clay body. Perhaps a flame-ware body might accommodate lithium carbonate.

Devil's Playground Granite Glaze Tests Round 3: Video

From my first and second round of testing, I realized that my granite needed more flux. It was too stiff and this was making the glazes uninteresting. So I set out to test every flux I could think of in the Utah State University materials store room. I added 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45% and 50% of each of these fluxing materials to my Devil’s Playground granite (which accordingly went from 95% down to 50%).

This was a broad test and I was hoping to hit on some interesting things, but I also just wanted to see the effect of different materials. When I leave USU, I am not going to have access to such a range of potential ceramic ingredients. The granite offers a blank slate with which to experiment, in a way; it is a stiff grey translucent glaze on its own at cone 10.

I was particularly interested to see the differences that the fluxes had on the granite. For example, the difference between minspar and custer feldspar (very minimal difference) or between lime and wollastonite (a marked difference, lime being much more green and faster at matting out the surface, the wollastonite being much bluer).

I also decided to add 4% iron to every test, in order to see how the added iron content played with these various fluxes, too.

This video is about 25 minutes long and takes you through the results of each set.

Check out my next post for all the notes and photos of this batch of tests.

Devil's Playground Granite Glaze Tests Round 2: Pictures with notes

The first test here is to see how the granite responded to increases in silica and alumina. Basically this was to see if the granite was deficient in either. I used Ian Currie’s sample Earthenware set but subbed in my granite for the ferro frit. I made up 4 corner glazes and then mixed 35 glazes from these. Each corner glaze is made from 300g material and topped up to 500ml.

Corner A Glaze contains 120g EPK (Edgar Plastic Kaolin) to 180g granite. This is our high alumina corner.

Corner B Glaze contains 75g EPK, 120g silica and 105g granite. This is our high alumina, high silica corner (low flux).

Corner C Glaze contains 300g granite. This is our high flux corner.

Corner D Glaze contains 150g silica and 150g granite. This is our high silica corner.

DP 221-255

What do we notice from these tests?

Corner C is the granite on its own. It melts at cone 10 and is pretty much a glaze on its own! In fact out of all of these tests corner c is about the nicest.

As we might expect, the corners A, B and D were not successful glazes. They were each too refractory and did not melt. In fact, from this initial test I can conclude that the granite has plenty of alumina and silica already. But it can take some alumina and silica, which may be helpful if I need to adjust it to fit the body better: ie. if I have crazing issues I can add some silica to the glaze without it drastically altering it.

The soda seems to be encouraging a more chestnutty brown color overall. Not particularly pleasant! Number 25 in this grid of 35 looks like a potentially nice shino style glaze in soda though.

Overall far too many of these tests are dry… the whole set needs more flux added.I can conclude from this that my granite needs flux added.

Here is the sheet showing the % of what each of these glazes are. This grid method comes from Ian Currie by the way. He has a couple of excellent books out there detailing how to do it.

Adding iron to this initial set did not improve matters. It needs more flux clearly. Below is the same grid test but with 4%, 7% and then 9% yellow iron oxide.

DP 256-290 (same grid as 221-255 with 4% iron oxide added).

DP 291-326 (same grid as 221-255 with 7% iron oxide added).

DP 326-360 (same grid as 221-255 with 9% iron oxide added).

In this next set I used the same exact table of kaolin and silica but added 10% lime and 10% minspar to the base granite (DP31). Using this as my corner C I ran the same set of tests. These were more successful, with the 9 glazes in the bottom left of the grid all being reasonably successful. Adding more flux certainly helped.

Compare this with the first picture of the blog… this is the difference in adding just 10% lime and 10% minspar. Much nicer results… the brown swathe of glazes is receding! I could push this further though-adding more than just 10% lime and minspar.

Here is the sheet showing the % of what each of these glazes are.

Below is this same set (DP361-395) with 4%, 7% and then 9% yellow iron oxide added.

DP 396-430 (same grid as 361-395 with 4% iron oxide added).

DP 431-465 (same grid as 361-395 with 7% iron oxide added).

DP 466-500 (same grid as 361-395 with 10% iron oxide added).

What do we note from these iron additions?

10% is overkill… the glaze becomes oversaturated and goes a kind of gun metal matte brown/black. The 4% ones look the brightest to me, more so than the 6% gang.

There was some exciting red spots in the bottom row of the 6% tests though. This happened more in the 4$ tests in soda. In general the soda tends to matte out the glazes a bit. Definitely a tenmoku to be found here though! Quite excited about some of these results.

. . .

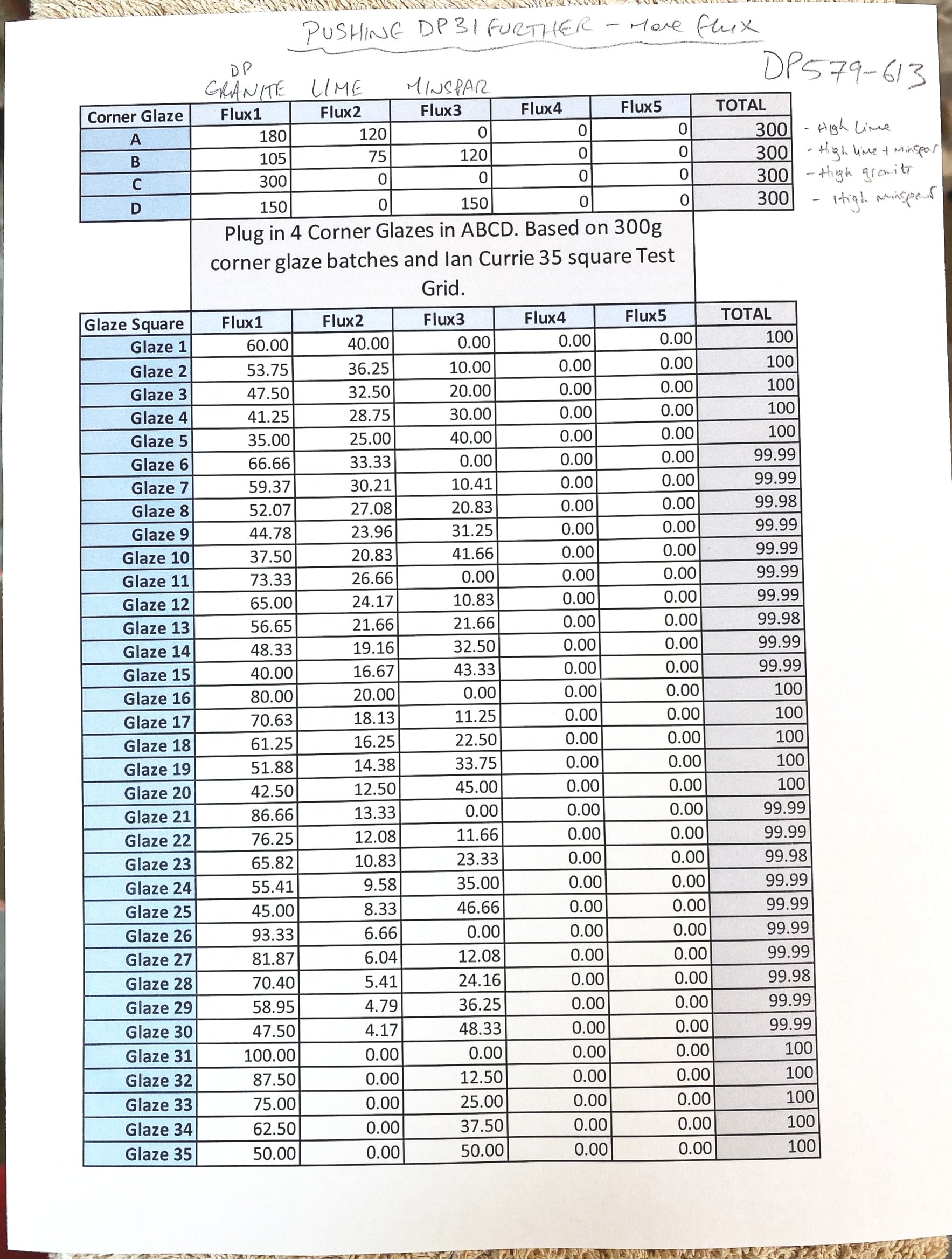

In this grid set I made a fluxier test. I have been using 10% lime and 10% minspar as a basic addition to my Devil’s Playground granite (DP31) but wanted to see what happened if I added more than this.

Corner A Glaze contains 120g lime/whiting (40%) to 180g granite (60%). This is our high lime corner.

Corner B Glaze contains 75g lime (25%), 120g minspar (40%) and 105g granite (35%). This is our really high flux corner.

Corner C Glaze contains 300g granite (100%). This is our pure granite glaze.

Corner D Glaze contains minspar (50%) and 150g granite (50%). This is our high soda feldspar corner.

Results of the test above: curious results! Where too much lime is included we get matte glazes, even in reduction (around corner A). The same does not happen around Corner D. This is the high minspar corner. In general the soda makes the glaze more matte and more green compared to the straight gas reduction.

There are quite a few decent glazes in this grid test though. We can conclude that the granite wants more flux but not too much (in terms of lime we start to get matte crystals at glaze 18 which has 16.25% lime and 22.5% minspar. For the pure lime it starts to get cloudy at 20%. I can conclude from this that 15% is probably the max lime content I want unless I am shooting for a matte glaze. The grid tests are fantastic but don’t show how drippy the glazes will be. I need to run this test with vertical test tiles too.

Minspar tends to send the glaze grey on its own so a blend with lime is good for the bluer color.

Here is the sheet showing the % of what each of these glazes are.

Next up I added bone ash to DP31 (the fluxier base granite glaze which has 80% granite, 10% lime and 10% minspar in it). DP501 has 1% bone ash in it, Dp502 has 2% and so on up to 10% at DP510. Then DP511 has 15% bone ash and DP512 has 20% added. Then the next set of three DP513-524 is the same base glaze but with 4% yellow iron oxide added. The next set DP525-536 is the same base glaze but with 7% yellow iron oxide added. The next set DP537-548 is the same base glaze but with 10% yellow iron oxide added.

The tests were all fired to cone 10. The top line of each of these tests is in reduction, the second set is gas oxidation and the final is gas soda.

Here are the tests individually so we can see them a little easier. This is the straight up bone ash additions (to DP31): 1,2,3,4,5,6,7,8,9,10,15,20%.

DP31 glaze with bone ash additions: 1,2,3,4,5,6,7,8,9,10,15,20%.

Generally the oxidation ones tend to be greener and the reduction ones bluer. The bone ash doesn’t have a huge impact until about 6% is added, then the glazes start to get a bit cloudier. This progresses all the way up to 20%. None are fully matte though. I was hoping for a greater impact from the bone ash frankly… aiming at a chun. More testing needed to get there!

In soda the glazes were greener and satiny: the bone ash did not have a huge impact.

Now here is the same tests with 4,7,10% yellow iron oxide added…

DP31 glaze with bone ash additions: 1,2,3,4,5,6,7,8,9,10,15,20%. Plus 4% iron oxide.

The addition of 4% iron led to a greenish black in oxidation and reduction… not particularly attractive when thin. In soda there was some potential in the 10-20% bone ash zone. Some nice reddish flecks happening there.

DP31 with bone ash additions: 1,2,3,4,5,6,7,8,9,10,15,20%. Plus 7% iron oxide.

The 6% addition of iron made the tests richer in oxidation and reduction. In reduction they were more interesting: got some red/brown flecks in the black. The flecks were there even from 1% bone ash upwards: not a big difference between them.

The soda tests were affected heavily. The tests got redder and increasingly interesting. 20% is pretty cool!

DP31 glaze with bone ash additions: 1,2,3,4,5,6,7,8,9,10,15,20%. Plus 10% iron oxide.

The 10% addition did’t change much in oxidation but reduction ones were quite interesting. John says these could do with more flux but could be nice. More running! I do like DP542-545 especially. Test more around this area.

In soda the glazes did start to run where hit heavily. Nice red flecks though! DP545-8 to be pursued for sure.

Okay, next set. In this one I am aiming at a yellow mate glaze.

In the first set (the top 3 rows) I added dolomite. DP549 has 2% dolomite added, DP550 has 4% DP551 has 6%, DP552 has 8%, DP553 has 10%, DP554 has 15%, DP555 has 20%, DP556 has 25%, DP557 has 30%, DP558 has 40%. In the second batch of tests here I added 1% yellow iron oxide. In the third batch I added 10% zircopax and then finally 6% titanium dioxide.

Here are the tests individually. First set with just the dolomite additions.

DP31 glaze with dolomite additions, from left to right: 2%, 4%, 6%, 8%, 10%, 15%, 20%, 25%, 30%, 40%.

Results from the test above: we can see that the reduction tests are bluer, the oxidation ones greener and the soda ones are a darker, more matte, green. In general with all of the tests as you add more dolomite they get lighter in color and a matter surface.

In the oxidation and reduction tests it takes 10/15% to matte out the glaze. In the soda they were all pretty matte, but certainly from 4% upwards. Progressively so! More flux necessary to balance this out. Although none of these were that exciting to me.

DP31 glaze with dolomite additions, from left to right: 2%, 4%, 6%, 8%, 10%, 15%, 20%, 25%, 30%, 40%. Plus 1% iron oxide!

Results from the test above: these were similar to the DP549-558 above, just a shade darker, and a bit fluxier. This is what I would expect from a 1% iron addition. DP562-4 were pretty nice in reduction I think: compare to my wood ash tests.

DP31 glaze with dolomite additions, from left to right: 2%, 4%, 6%, 8%, 10%, 15%, 20%, 25%, 30%, 40%. Plus 1% iron oxide AND 10% zircopax.

Results from the picture above: the gas and oxidation ones were fairly mankey (english for gross) as were most of the soda ones… until DP577-8. DP578 is full on yellow! This is very exciting. I need to do more testing around this as it is fairly drippy here but definitely close to a finished glaze I reckon. I wonder what it would look like with different levels of iron. Maybe some tin to brighten it. Perhaps some silica or clay to stop it melting too much.

Here’s that tile on its own…

Now I added 6% titanium dioxide to this whole set of tests.

DP31 glaze with dolomite additions, from left to right: 2%, 4%, 6%, 8%, 10%, 15%, 20%, 25%, 30%, 40%. Plus 1% iron oxide AND 10% zircopax AND 6% titanium dioxide.

Overall I’m not super into these. The titanium makes some crazy blue/purple hazy business happen. It also makes the glazes much more melty. The ones with 30/40% dolomite ran a whole lot in the soda. The yellow is still there but has a greener cast. The winner is still DP578 from this batch of tests I think.

Devil's Playground Granite Glaze Tests Round 2: Video

This is the second batch of tests I made with my Devil’s Playground granite. Based on my initial tests I wanted to take a step back and do a few basic grid tests to discover more about the composition of the granite. I do intend to do an analysis of the granite soon but wanted to see what I could learn using Ian Currie’s grid method first.

Ian Currie has a couple of excellent books which outline his method. Here’s his website if you fancy getting them. There are still copies to be had out there.

I explain the basics of the grid method in this video, as well as the results of my testing.

Watching the video is probably an easier way to see the results than reading my notes but I will outline them in my next blog post anyway. I will document the results with photos and discuss them further. And also explain my plan for the next set of tests!

EnVision: a Woodfire Invitational — WOODFIRE NC 2022

The COVID-19 pandemic caused WOODFIRE NC to be postponed twice. It was great to be able to actually get together and make it happen!

This blog documents the EnVision show that was set up at the conference. It had work from all of the presenters and artists invited to be part of WOODFIRE NC. It was fabulous being able to walk through the main hall and see these pieces throughout the conference. I have tried to document each piece and artist that were in the show but if I mislabelled any then please let me know!

For the first WOODFIRE NC conference back in 2017 I documented the show as well. You can check that out via the link below if you like:

But now it is 2022! Below are images of almost all of the pieces in the EnVision show. The images below are all cropped square but clicking on any one of them will enlarge them. Then you can flick through the un-cropped images at leisure!

There were some other pieces on display at the conference. This was Anne Partna’s Invisible kiln, full of her work and other local artists such as Hannah Cupp and Stillman Browning-Howe.

Some of the wild clays that Takuro Shibata uses in his Starworks clay blends…

Catherine White’s clay paintings were particularly exciting to me. These were done with different colored unfired clays onto bisque tiles. Catherine calls them ‘Wild Pigment Paintings.’ I hope they stay on permanent display at Starworks.

Devil's Playground, Western Utah. The place!

Here is a little tour of where I am sourcing the granite to make granite glazes from. It is located in Western Utah. Very beautiful spot!

Here is a little video I took to get you situated…

And now some photographs of the place…