Devil's Playground Granite Glaze Tests Round 4: Notes and Pictures

In this blog post I discuss the results from my fourth round of granite glaze tests. In the last post I showed the results of my yellow glaze research which were pretty promising.

Th eother main avenue of testing this round was in trying to hone in on my tenmoku glazes. This did not go exactly as I expected but I have a plan for how to move forward. I also ran a couple of extra material tests to see what would happen: adding tin oxide and salt to my granite. These results are at the end of the blog post.

First up though let’s look at the tenmoku tests. I chose to do two different base glaze recipes to see the difference between using wollastonite and lime as the main flux in these iron rich glazes. I made two different bases and then added 1-10% iron oxide to them. This was the first set of each and then I added 10% bone ash to the lime based tests, and zinc oxide to the wollastonite ones.

Lets look at the lime set first:

You can see that the base was too fluxy, even in just gas reduction. At 5% iron added the glaze started to run, and above 7% it definitely ran. In soda they were all on the move.

Here are a couple tiles from the first set using just lime as flux. The top two tiles here are just the base glaze, using lime as a flux. You can see that even with no iron added the glaze is pooling at the bottom of tile 1076. You can also see that it is badly crazed. In DP 1085 (which has 9% iron oxide added) the glaze ran a whole lot as iron is a flux too.

Now is DP 1085 plus 10% bone ash. In my previous tests bone ash added some jazz to the tenmoku glaze. It is kind of hard to see the effect here but there are some reddish flecks.

Here is what happened when I applied these glazes with the bone ash added to larger times that were fired flat (DP 1087-1097):

I think there is something interesting here: a kind of chun glaze happening. Especially at DP 1091 which has 4% RIO and 10% bone ash. I am a bit wary though. The vertical test tiles do not have as nice a surface. These larger tiles are fired flat, so do not show the drippiness. The chun like effect seems to be happening where the glaze is thick and settled (a factor that usually leads to glaze flowing too). I would like to pursue this though.

The tests in the soda all ran like crazy and I was not totally into any of the tones.

In general I need to stiffen the base glaze. I think a likely base would be 60% DP, 20% BASALT, 15% LIME, 5% EPK. This may not be stiff enough even so I plan to do some experiments up to 15% EPK added and lowering the lime to 10%. I want to add silica too.

Okay now let’s look at the other base glaze where I used wollastonite instead of lime. The base was 60% DP, 20% BASALT, 20% LIME. This was also too fluxy as you can see. i was kind of into the DP1099 in soda. None of the tenmokus really came out. I got better results from the lime set.

Adding zinc oxide stiffened the glazes considerably, which is a nice property. Some of my previous tests had more jazzy effects from the Zinc. I am curious why this didn’t happen here. At 20% I should have seen more jazz. I think maybe it had something to do with the iron not being well sieved in my previous test. I think maybe iron sprayed on would create seeds that zinc would get excited about.

I think it is worth showing the base tests side by side too. The top row clearly shows the difference of using lime compared to wollastonite. The lime seems to bleach the iron out less (although this is not the best test as I used 20% wollastonite compared to just 16% lime). In soda the wollastonite tended to make the glazes yellower.

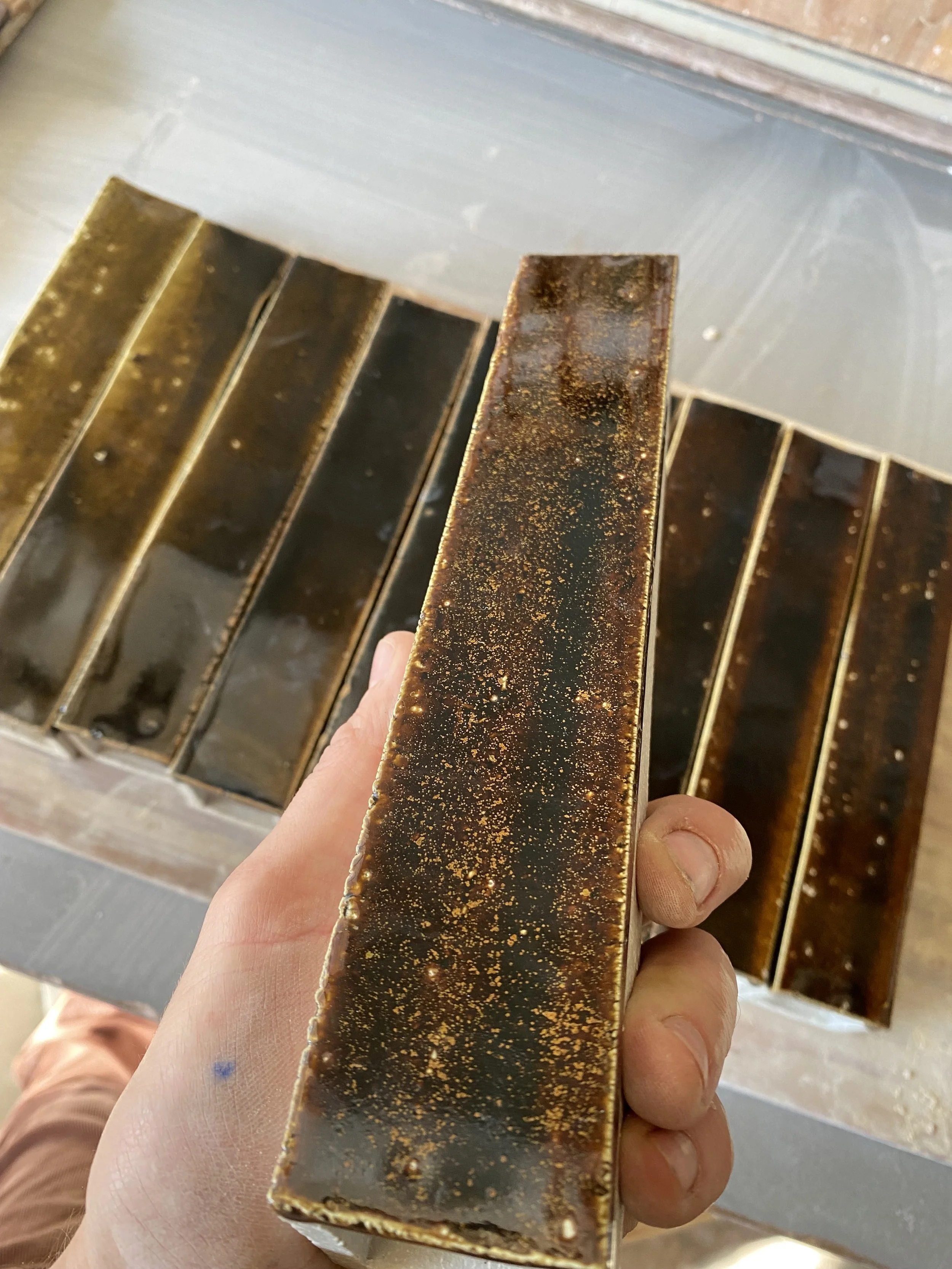

Finally, here are a couple extra tests that I did not get round to before. Here is what happened when I added tin oxide to my Devil’s Playground granite.

These results were not particularly exciting. In general we can say that the tin acted as an opacifier. At higher levels it made the glazes kind of shino like. Could be more interesting when added to other glaze but nothing here to pursue really. Tin is also expensive so I was only really doing this out of curiosity, in case I found something spectacular.

Now here is a final experiment. I added salt to my granite. 5 up to 50%. Initially when opening the kiln to see these tests I was baffled. The glaze kind of migrated!

When I first saw these tests I said “well, I never need to do that again,” and “now I can tell people just to not put salt in their glaze, unless they want it to run away.” I thought that this had happened because salt vaporises at a low temperature. I assumed it was something to do with this. But Louis Katz, a Professor at A&M University in Corpus Christ, Texas messaged me to say:

“I think this is because the glaze coat did not dry. Salt slows it. The steam in the heating causes a weakness in the mechanical hold the glaze has on the bisque. Expect the clay body to bloat. The eutectic with salt (even its melting temp) is so low that it seals over the clay well before all the carbonates and sulfates in the clay have time to escape. I think that if you dried out the sample at 212 and then slowly raised it a few degrees over an hour you would get less or no crawling.”

This is intriguing! So not I am eating my words and will have to do another test. I will not run this whole test again but probably just do a few test tiles to test Louis’ theory.

Okay well, thats all for now. Until the next round!